2007 News Release

Jefferson Lab Cooks Up the Perfect Cavity

This graph shows the test result for one ILC baseline design cavity. This cavity achieved an accelerating gradient of 42 MV/m, a result consistent with the theoretical limit of this particular cavity design.

While it's said that opposites attract, particle physicists are taking no chances. In hopes of learning what the universe is made of, they're preparing to build a machine that will accelerate and smash together electrons and their opposites, positrons, 14,000 times every second. Like Jefferson Lab's Continuous Electron Beam Accelerator Facility (CEBAF), the proposed new machine, the International Linear Collider (ILC), is being designed to use superconducting radiofrequency (SRF) cavity technology.

Drawing on their world-class expertise in SRF technology, Jefferson Lab scientists are assisting in validating the processing methods used to build and prepare ILC accelerator cavities -- the components that will store the radiofrequency waves used to accelerate the electrons and positrons -- for installation. Jefferson Lab scientists have developed a program designed to consistently test the absolute limit of an accelerator cavity's performance, and one baseline design cavity they tested, manufactured by ACCEL Instruments GmbH, achieved an accelerating gradient of 42 MV/m, a result consistent with the theoretical limit of this particular cavity design.

"So we've made the perfect cavity. The only way we could make it better would be to continue doing it consistently," says John Mammosser, an Institute for Superconducting Radio Frequency Science and Technology (ISRFST) senior engineer and the leader of the Jefferson Lab ILC cavity processing work.

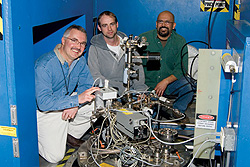

John Mammosser, Damon Bice and Ralph Afanador, a Jefferson Lab technical associate, pose inside an open Vertical Test Chamber. ILC baseline design cavity A7 sits in a tank of liquid helium concealed beneath the circular stainless steel lid in the floor.

The Americas region of the ILC Global Design Effort sent the first two of a series of prefabricated niobium accelerator cavities to Jefferson Lab for initial screening and performance tests. Each cavity is subjected to a process called electro-polishing. This process resurfaces the interior of the cavity by etching away an exceedingly thin surface layer, much like a chemical facial peel sloughs off dead skin cells. This is followed by a thorough cleaning and assembly process before installation in the Vertical Test Area. In this test, the cavities need to demonstrate an accelerating gradient -- the ability to stuff energy into particles -- of 35 Megavolts per meter (MV/m) to meet the ambitious ILC design specification.

Jefferson Lab staff will process and test both cavities multiple times. Between the tests, the cavities again receive a light electropolishing followed by thorough cleaning.

"Every time you give a cavity chemistry, it has a totally new surface, and it can have a totally different performance," Mammosser says. Both ILC cavities will eventually undergo four treatment/test cycles. These will be followed by cavities from other suppliers around the globe.

The cavities have so far performed well in response to the processing program, with one not only surpassing the design goal, but also reaching, within measurement uncertainty, the theoretical limit of this cavity design's performance. "It's great news for JLab, it's great news for the Americas region, and it's great news for the ILC, because this cavity has tested out beyond spec. In fact, It's the only one that has reached this level of performance at the temperature at which the ILC will function," Mammosser explains.

He says the cavity test results are even more remarkable when taken on the whole: The first cavity achieved 19 MV/m, 29 MV/m and 25 MV/m; the second has attained 29 MV/m and 42 MV/m, so far. Although the cavities have not met specification on every test, the limit has been due to defects in materials or fabrication (quench-limited) and not because of surface contamination due to processing (field emission), a problem that has, in the past, plagued all cavity processing programs.

"Before, we've had so much field emission that you couldn't find the limit. Now we're consistently reaching the limits of the cavities," Mammosser says, "In fact, so far, all cavity tests have reached their limits. And none of them have been field-emission-limited."

Mammosser credits the Institute's development of, and strict adherence to, improved rules for handling, cleaning and assembling cavities for the elimination of the limiting effect. Reducing the remaining spread in cavity performance is one of the key challenges for the ILC.

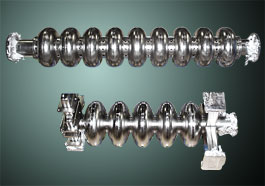

Shown are two different accelerator cavity designs - an ILC cavity (above) and a cavity from Jefferson Lab's CEBAF accelerator (below). Jefferson Lab's recent refurbishment of CEBAF accelerator components is also consistently achieving field-emission-free performance, thanks to these Institute developments.

The ILC community is pushing the technology of superconducting radiofrequency technology out beyond the cutting edge, with the goal of building a machine with linear accelerator cavities that each operate very efficiently and consistently. The baseline design cavities so far tested represent just one of many cavity designs, with each design offering unique features and potential drawbacks.

"If you change the shape of the cells that make up the cavity, you could potentially push beyond where we are now," he says.

While comparing the different designs has proven difficult, Jefferson Lab's optimized procedure now makes it possible to compare the accelerating capabilities of different cavity designs consistently and quickly. "The ILC needs to get enough data to know which design to choose. We're in a good position now to do that. We do all the chemistry and testing in-house, and we're able to process a cavity a week," Mammosser explains. "We're anticipating receiving some additional cavities with some of the advanced designs, because we've demonstrated that we can reach the cavities' limits."

By going to a second shift, the ILC cavity testing rate of one-a-week can be achieved without impacting the Institute's commitment to support top priority internal projects (for the 12 GeV Upgrade and 6 GeV hardening)

"We're still early in the process. One data point doesn't make an ILC, but it's encouraging to get to this point this early in the game," says Robert Rimmer, head of Jefferson Lab's ISRFST. "We thought we might be at this position after the first year, but we've actually gotten there on just the third attempt. Now we have to show we can do it consistently."

"Testing of these cavities has demonstrated that JLab is capable of processing and testing cavities that perform at the limits of the technology. Now we are poised to qualify additional suppliers, including domestic suppliers, which will greatly expand the world capacity for cavity production, to the benefit of all superconducting accelerator projects," says Warren Funk, former director of the Institute and member of the ILC Global Design Effort.

This work is being conducted under a Memorandum of Understanding with Fermilab. For instance, Damon Bice (pictured above), a Fermilab senior technician, is spending a year at Jefferson Lab to learn the process of cavity processing and testing.

At least one other similar cavity has also reached the calculated theoretical limit of this cavity design. The cavity was processed at The German Electron Synchrotron DESY, and it also tested, within measurement uncertainty, near the theoretical design limit of the cavity.

For More Information

Reaching New Heights in Accelerator Technology

Thomas Jefferson National Accelerator Facility’s (Jefferson Lab’s) basic mission is to provide forefront scientific facilities, opportunities and leadership essential for discovering the fundamental structure of nuclear matter; to partner in industry to apply its advanced technology; and to serve the nation and its communities through education and public outreach. Jefferson Lab, located at 12000 Jefferson Avenue, is a Department of Energy Office of Science research facility managed by the Jefferson Science Associates, LLC.